How to Feed an Army

Go behind the scenes at the Massachusetts military lab engineering the fuel of the future.

“Remember in the first Terminator movie, when they’re crushing the Terminator? That’s basically what this machine does,” says Wesley Long, an equipment specialist in the Combat Feeding Division. The machine in question is capable of applying 20,000 pounds of downward force—roughly the equivalent of piling on seven standard compact cars. It has an official name, but everyone at the United States Army Research Institute of Environmental Medicine (USARIEM) in the Natick Soldier Systems Center refers to it as “the Crusher.”

The Crusher’s objective is to determine whether the contents of cardboard boxes can survive being squashed beneath an avalanche of military gear. Should a box and everything in it make it past the Crusher, Long subjects it to other forms of abuse, from a vibration test simulating the jolts endured in the back of a Jeep bumping along rough dirt roads to a drop test that mimics falling out of an airplane.

“They make it, I try to break it,” Long says. Even the tiniest crack or dent could have devastating consequences. Long tests everything from ballistic plates to helmets to ammunition, but the majority of his time, he focuses on one particularly precious cargo: food.

“When people think of important factors for the military, they think of cool technology, like body armor, robotics, what have you,” Long says. “However, food is the most critical thing for any warfighter.”

Long’s arsenal of destructive tools is just one facet of one of USARIEM’s Military Nutrition Division. This is by far the most technically sophisticated military food lab—some would say food lab, period—on the planet. And for more than 60 years, it’s been hiding in plain sight in the most unassuming location: a 10-minute drive from the local mall in Natick, Massachusetts, a suburban town west of Boston.

Natick Labs, the intentionally vague name the complex goes by, lies set back from the main drag of Route 9, shielded from commuter traffic by patches of trees. Locals in the area generally pay the lab little mind. I know this because I grew up 10 miles from here, oblivious to what lurked a stone’s throw from the Olive Garden and Dunkin’ Donuts.

For as long as humans have been fighting each other—in other words, for as long as humans have been around—wars have been won and lost based on caloric resources. Cutting off a besieged city’s supply routes or destroying an invading army’s food stores can put a swift end to any military campaign. Both the necessity and financial incentives created by warfare have led to some of the most significant technological advancements in culinary science.

“An army marches on its stomach,” said Napoleon Bonaparte—or possibly Frederick the Great, to whom the famous line is sometimes attributed. Regardless of who actually said it, Napoleon knew that his greatest challenge in achieving his dream of continental conquest would be feeding his army. If the French troops were going to make it to Russia, they needed food they could carry with them for months without spoilage. Bonaparte offered up 12,000 francs as a prize for anyone who could figure out a new preservation method. The cash incentive would spur confectioner Nicolas François Appert to invent canning.

“The military could only fight as far out as supply chains,” says James McClung, chief of USARIEM’s Military Nutrition Division. “So when Napoleon’s Army finally figured out canning, sterilization, and pasteurization, the supply chains went further out. It revolutionized the military.”

In doing so, it also revolutionized the way the world eats. Canned foods are now ubiquitous. So are air fryers, M&Ms, freeze-dried foods, and dozens of other innovations consumers now take for granted—all of which are the direct result of U.S. military funding.

“It was really overwhelming to me how many military-related food influences there were, both in terms of items that were developed by the military or by food science research that was funded by them,” says Anastacia Marx de Salcedo, author of Combat-Ready Kitchen: How the U.S. Military Shapes the Way You Eat. By her estimation, roughly half the products in the average American supermarket contain some element of military-funded technology.

(Learn more about some of history’s most notable—and notorious—military diets.)

“The same values that are sought in developing combat rations also appeal to corporations,” Marx de Salcedo says. “They’re looking to extend shelf life. They’re looking to make sure that they’re rugged, that they’re easy to ship. They’re looking to appeal to a broad array of palates.”

From the plastic packaging used to hold salad greens to the nuclear energy-irradiation process used to sterilize spices, military tech is everywhere in our food supply chain. And almost all of it started right here at Natick Labs.

When a pair of heavily armed guards escort the photographer and me into the entrance of the facility, the sheer scale of it all quickly becomes apparent. What looked like a collection of squat, nondescript buildings from the road is actually a sprawling 78-acre campus. Natick Labs is a Russian nesting doll of laboratories, a 900-employee complex that encompasses everything from a fire lab to stress test facilities where hyper-realistic combat simulators challenge soldiers’ physical limits.

But the Metabolic Kitchen, the lone culinary research and development center for the world’s most technically advanced military, is what I’m after. This is the place that developed pizza that can survive for three years without refrigeration; a strangely convincing approximation of key lime pie that can be sucked through a tube at 9Gs, or nine times the force of gravity; dehydrated chili that can endure an Antarctic expedition; and ice cream that can go into outer space. I’m here to find out how.

First, let’s get one thing out of the way: MREs, or Meals, Ready-to-Eat, do not have the greatest gastronomic reputation. To date, videos of civilians trying MREs have racked up more than 990 million views on TikTok. Commiserating over military meals is a trope in war movies and practically a basic training rite of passage. I had always assumed taste was a negligible factor—but it turned out I was very wrong.

“If [the MREs] don’t taste good after three years, is the soldier going to eat it? And how nutritionally helpful is it if they’re not going to consume it?” says Lauren Oleksyk, team leader of the Food Processing, Engineering and Technology Team at Combat Feeding.

Oleksyk has spent decades trying to make MREs taste better and last longer. She is one of the primary reasons soldiers in the field now have access to pizza; she cracked the code on bread; and in 1993, she was on the small team that invented the Flameless Ration Heater during the Gulf War. All of these items are manufactured elsewhere, but the technology was developed right here.

“We just do the science—but there’s a lot of science,” Oleksyk says. “Rations are issued all over the world so we have different climates they have to withstand. It could be the Arctic, it could be the desert, it could be the jungle. It could be high altitude or low altitude. These MREs are dropped out of aircraft, sometimes without parachutes. What happens when they hit the ground?”

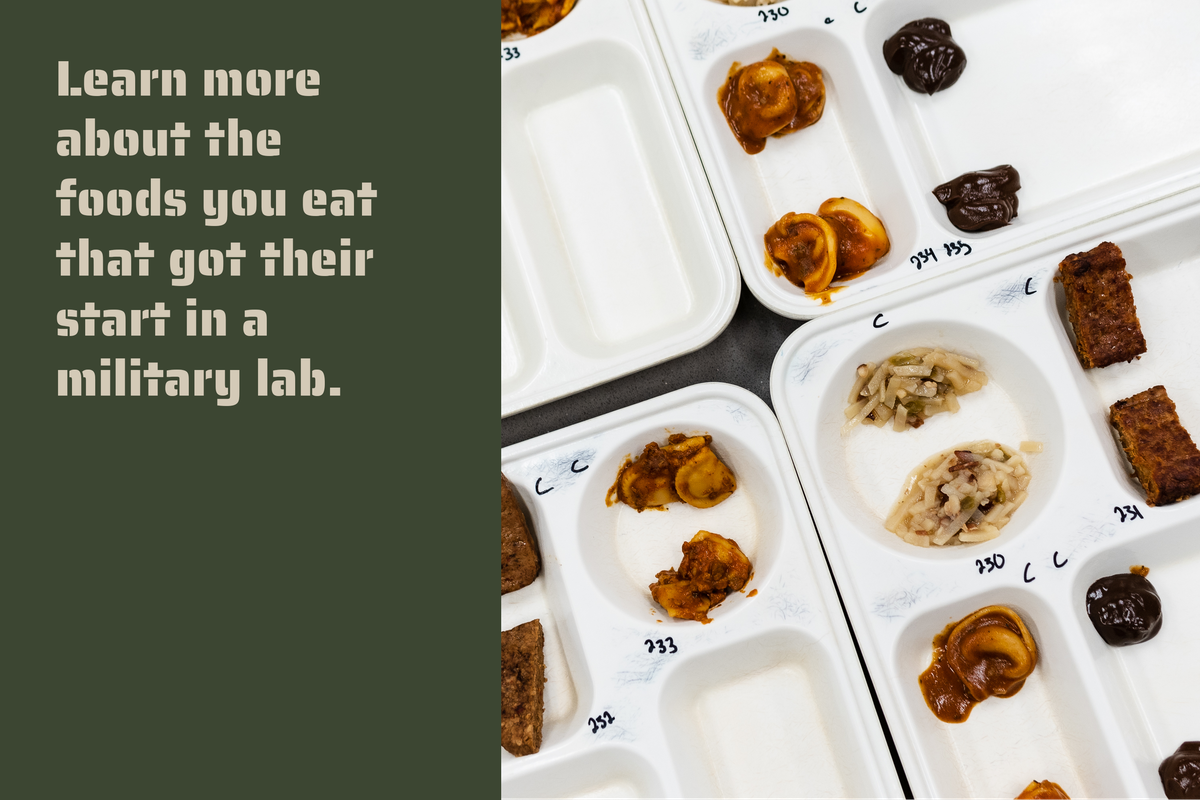

On the wall of her office are a series of framed patents, and on the table in front of me is a small feast that resulted from those patents. Our lunch for the day consists of four different MREs currently in the field: Mexican chicken stew, hash browns with bacon, beef ravioli, and creamy spinach egg noodles.

The mechanism for heating each of them up hinges on the rapid oxidation of powdered magnesium contained within a pouch. Within 12 minutes, this chemical reaction can heat the contents of the MRE to 100 degrees Fahrenheit without the need for a fire. For meals with larger groups of soldiers, there’s a scaled-up version that can heat 18 MREs simultaneously. Like the best tech, it’s stupid-simple to operate—you just add water.

In the field, the entrees are just one component that comes inside the dull, brown plastic packages. About the size of a fold of newspaper, each MRE contains a series of items: dry crackers with cheese spread or peanut butter, a disturbingly small supply of toilet paper, creamer for coffee, and so on. Since each MRE has a different mix, soldiers often rip open the packages and trade for coveted brand-name extras, such as M&Ms.

One nonessential that I can’t help but notice: a tiny bottle of Tabasco hot sauce. Those few milliliters of capsicum have been a sticking point for decades; after introducing the miniature bottles in World War II, the military replaced them with more efficient packets, only to later bring them back. As inefficient as the packaging may be, the team at Natick Labs deemed the morale boost worth the extra fuss.

More pragmatic is the stick of caffeine gum, a straight legal stimulant to gnaw on when there’s no time to make coffee. Jeff Sisto, a former active duty Marine, points out that the meal before us represents a significant upgrade from the MREs he used to eat. “When I was in the Marine Corps, soldiers and marines would take the coffee pack and just slice, chew, or dip it, almost like chewing tobacco,” he says. “When you have to pull a guard duty, three in the morning till six in the morning or whatever your shift is.”

Oleksyk demonstrates how to activate the heater. The packaging on the back of the “creamy spinach egg noodles” contains a diagram and the helpful instruction to lean it up against “a rock or something.” “We left it on there as a joke,” Oleksyk says. “And now there’s a ‘Rock or Something’ rock band. There are t-shirts.”

Making sure that the soldiers appreciate the MREs enough to actually eat them is a battle Oleksyk and her colleagues have been fighting for decades. Panels of soldiers in the field taste test and rate every MRE, in addition to answering surveys. One of the biggest conundrums about any sort of nutritional or dietary study, however, has always been the unavoidable fact that people lie about what they eat. To find out which MREs soldiers actually throw out, researchers sometimes resort to more hands-on methods. That means everything from fishing through their trash to analyzing the content of human waste.

While the spinach pasta looks less than appetizing when I rip open the package, the ravioli are a close-enough approximation of a can of Chef Boyardee and the “Mexican chicken stew” has a pleasantly spicy kick. As the demographics of both the military and the people it serves shift, Natick Labs has increasingly added in halal and vegetarian options. Mexican-inspired dishes are increasingly in demand, as are other international options.

“It’s a very different experience when you’re cold, tired, sitting on a mountain in Afghanistan or the desert in Iraq in the cold rain,” Sisto says. “Whatever it is, you appreciate it so much more.”

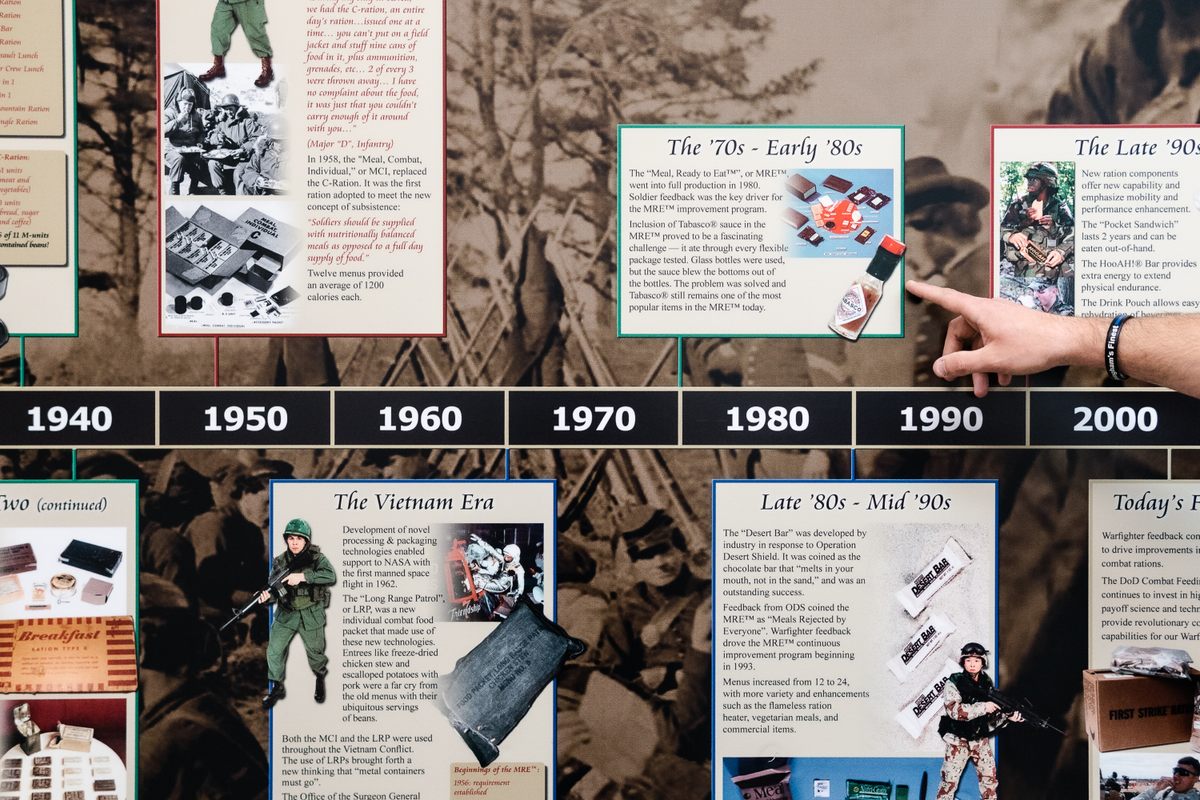

(Read more about the evolution of American military rations.)

Tom Yang is holding the future of military food in his hands. Cradled in one palm are 1,200 calories, all contained within five bars, each no larger than a matchbox. There’s a chewy barbecued bean bar, a crunchy Buffalo chicken bar, mac ‘n’ cheese bars with a texture just past al dente, and a Parmesan-spinach bar, which is the same dark, vibrant green as a Christmas tree.

“You can see how well this color, the chlorophyll, has been retained,” Yang tells me. “If you reheat this over the stove, the green vegetables will turn into gray mush. You’ll lose all the nutrients. But this was made six months ago and still has a very good flavor.”

I bite off the edge of the chocolate cheesecake bar. It’s harder than its full-scale sliced counterpart, but still coats the palate in a satisfying way. “You just had 300 calories in one bite,” Oleksyk says. “We’re the opposite of the consumer market. They want low-calorie everything, but the warfighters are out there burning thousands of calories a day.”

The Close Combat Assault Ration, as these tiny packages are known, represents the culmination of years of research. All of these items are shelf-stable for up to three years without refrigeration, and everything has a reasonably short list of ingredients I can pronounce and recognize. Edible, plant-based film encases each item, meaning there’s next to zero waste.

“People think, oh my God, military rations must be loaded with preservatives, but no, we didn’t add any,” Yang says proudly. “We don’t have to. The only ‘preservatives’ are a little sugar and salt. That’s it.”

The secret to these ultra-dense caloric nuggets is a device roughly the size of a large commercial washing machine called a vacuum microwave-dryer. “If we use conventional heat to drive away moisture, you have to rely on hot air from the outside to penetrate into the center,” Yang explains. “It will take forever. Also when the center is dry, the outside is already damaged because it’s been exposed.”

Since the turkey sausage patties currently rotating behind the machine’s glass door are dehydrating at 40 degrees Celsius instead of 100 degrees (104 degrees instead of 212 degrees Fahrenheit), the food never obtains that unpleasant “cooked” flavor that canned foods possess. By the time these sausage patties are done, they’ll lose 40 percent of their total volume, yet retain virtually all of their nutritional value. To reach the same state using a freeze-dryer would require two full days. These patties take 20 minutes.

Yang pulls out a finished set of turkey sausages stacked with slices of cheddar on a bun. It looks remarkably like a McDonald’s breakfast sandwich that someone accidentally sat on in the car. As with everything else Yang makes, it’s shelf stable for three years. “If you have shelf-stable pizza, you might as well have a shelf-stable burger,” Yang says. “I didn’t have to make it a double burger, but I think the soldiers like that. You smell that?”

It smells like, for lack of a better term, real food. In fact, just about everything that Yang sends through the vacuum microwave-dryer starts out as a recognizable food item—often cooked right here in this kitchen.

Rather than reinvent the wheel, he prefers to take familiar comfort items and keep them as recognizable as possible. Lately, he’s been popping whole Smucker’s Uncrustables in the device straight from the package. The sandwiches that emerge 15 minutes later bear a slight resemblance to shriveled empanadas, but taste virtually indistinguishable from the PB&J in a kid’s school lunchbox.

“We can provide soldiers with seven to 10 days of ration without resupply,” Yang says. “In the future, on the battlefield, we’re going to send in small units instead of whole platoons. So for them to be able to carry enough food without resupply is very critical.”

(Learn more about the foods you eat that got their start in a military lab.)

The goal of feeding an army has always been to allow its operatives to fight longer and travel farther. Now, technology is making that goal more attainable than ever before, often in ways that would have felt wild even in science fiction a decade or so ago. At the moment, Natick Labs is experimenting with 3D food printers that can render protein substrates—think thin sheets of lab-grown meat—into edible forms.

Not long after my visit, this lab would unveil a fully mobile “ghost kitchen.” Ghost kitchens are nothing new; as delivery apps have proliferated across the U.S., so have the industrial kitchens operating under the label of one or more phantom restaurants. While regular ghost kitchens employ legions of line cooks, just like their brick-and-mortar restaurant counterparts, this kitchen, which is roughly the size and dimensions of a shipping container, requires no human operators. In the not-so-distant future, the military will be able to air-drop these units just about anywhere, creating self-operational galleys thousands of miles from the nearest base.

Impressive though the “how” may be, the “why” at Natick Labs is that the wars of the future will be fought in increasing isolation, with soldiers and drone pilots operating in ever-smaller units and ever more remote locales. It’s a disquieting thought, somehow—one that’s hard to shake.

Bars like the ones in Yang’s hand will be used for much more than combat, however. Some will be air-dropped into refugee camps; others will be used as supplies for survivors of natural disasters, as the growing climate crisis makes floods, fires, and hurricanes ever more common occurrences around the planet. Although they’re called Humanitarian Daily Rations (HDRs) in these cases, the principle is the same. And at some point, virtually everything here will end up in the grocery store aisle. Someday, everyday consumers will stock up on snack bars with vacuum microwave-dried blueberries and bananas without thinking twice about where they originated.

And yet, a large portion of these foods will go to soldiers in some of the most remote, hostile environments on Earth. For Yang, however, it’s less about extending the combat capabilities of the “warfighter” and more about trying to give people a piece of home when they’re far from it. There is something deeply human about preparing food for another person, even and especially within the dehumanizing context of modern-day warfare.

Yang has worked at Natick Labs for 35 years and, by his own admission, is looking forward to retirement. What keeps him going, at least for a little longer, is the prospect of providing some small piece of the familiar to those who need it most. “Maybe someday they’ll have fried chicken,” he says. “All the American things.”

As we turn to leave, he says, “I cannot let you go without letting you taste my pineapple upside-down cake!” He hands me a yolk-colored confection with a single, jewel-like candied cherry in the center. “It looks pretty, doesn’t it?”

While pineapple upside-down cake may have its roots in 1950s America, looking at this compact confection, I can’t help but be reminded of a dessert from the other side of the globe. Yang’s creation bears a subtle resemblance to the pineapple cakes of Taiwan, where Yang was born. It feels like an amalgamation of two different kinds of comfort food from two distinct cultures.

“They just make this pineapple upside-down cake as if they were going to serve it in a restaurant,” Yang says, gesturing to the on-site kitchen. “I just take it and dry it for 30 minutes. That’s it. I didn’t add any preservatives. It’s all-natural.” The results are good enough that my photographer and I polish off the whole thing. Yang beams.

“I want soldiers to have real food,” Yang says. “And this is all real.”

Gastro Obscura covers the world’s most wondrous food and drink.

Sign up for our regular newsletter.

Follow us on Twitter to get the latest on the world's hidden wonders.

Like us on Facebook to get the latest on the world's hidden wonders.

Follow us on Twitter Like us on Facebook