The Utopian Promise Of RepRap, the 3D Printer That Can—Almost—Print Itself

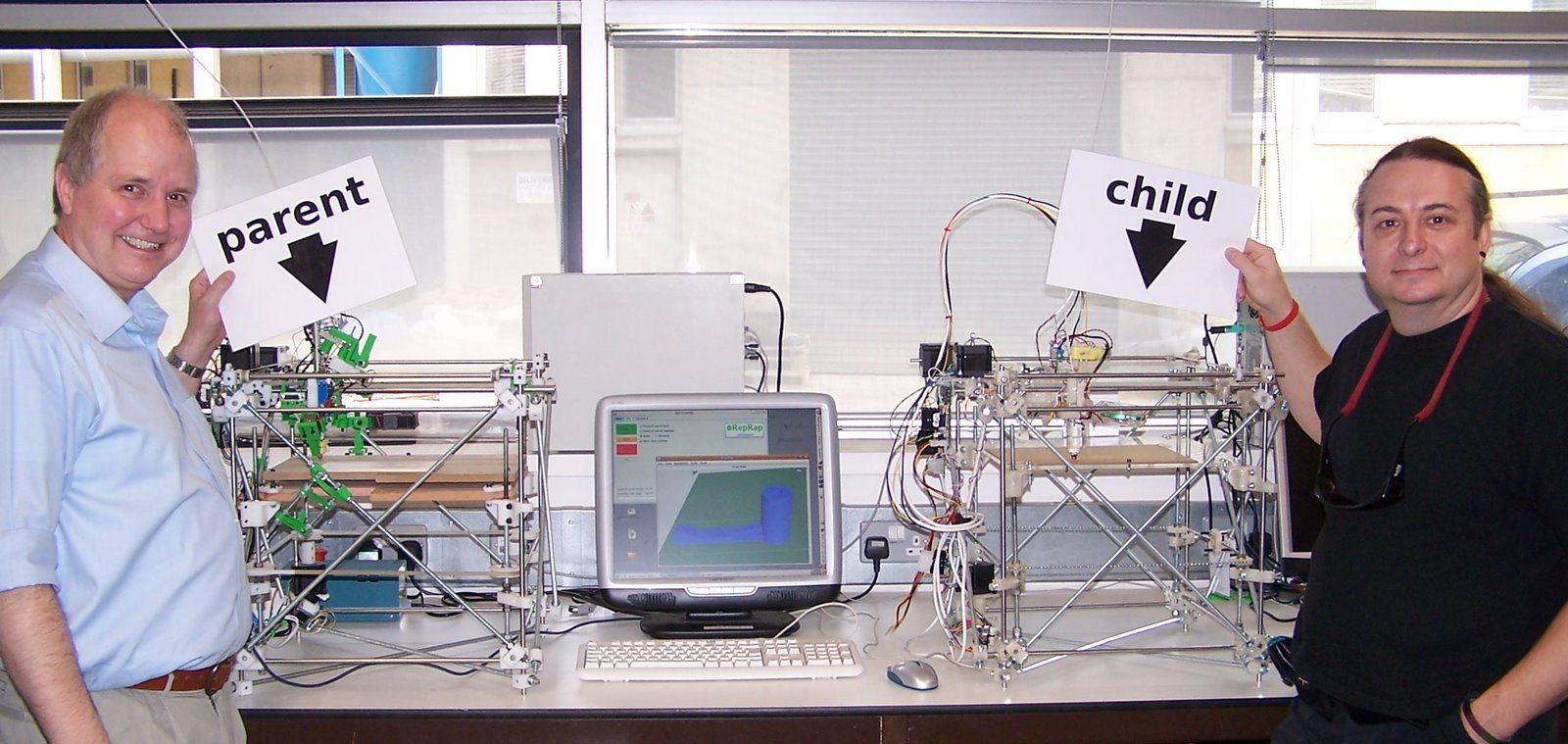

Bowyer and a volunteer, Vik Olliver, pose with the original parent RepRap and its first child. (Photo: Steve Baker/WikiCommons GNU 1.2)

In search of new skills for their technology, inventors have long turned to the natural world. In the past few years alone, robots have learned to run on water like basilisk lizards, drill like wood wasps, and detect sound waves with the precision and nuance of a bat.

But despite their many and increasing skills, machines lack one of the most natural of talents. Two animals can make a new animal; a plant can spawn a new plant. Even the simplest bacterium can split itself into offspring. But a machine can’t really have a child—right?

Meet the self-replicating rapid prototyper, or RepRap for short. While most 3D printers are extruding doodads and soap dishes, RepRaps spend a lot of their time making other RepRaps. Legions of volunteer engineers have spent the last decade trying to build the first machine that can copy itself. By applying Darwinian logic to technology, they hope to expand the 3D printer’s potential beyond the utilitarian and into the utopian.

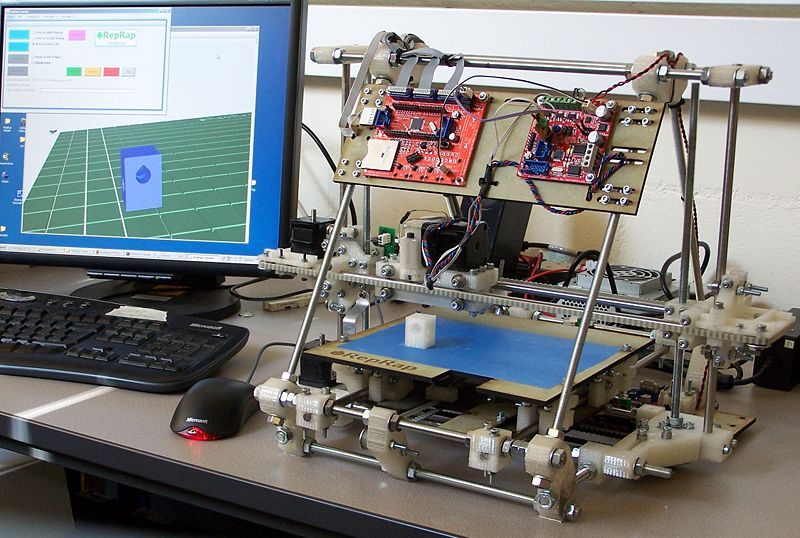

RepRap Mendel, one of the most recent common models. (Photo: Adrian Bowyer/RepRap Wiki GNU 1.2)

Rather than boasting cheetah-like legs or the slimming power of a cockroach, RepRap is based on broader principles that drive the natural world–reproduction, selection, and evolution.

“Ever since I was a child, I’ve been fascinated with the idea of self-replicating machines,” says Dr. Adrian Bowyer, the original mind behind RepRap. Bowyer was deep into his tenure as a mechanical engineering lecturer when his workplace, the University of Bath, acquired a 3D printer in 2005. Watching the machine digest ribbons of plastic into more useful shapes, “I suddenly realized that, for the first time, we had a manufacturing technology that stood a sporting chance of being able to make a copy of itself,” he says.

Aided by a grant from the British Government, Bowyer and his research assistant Ed Sells set to work. A year and a half after they started, a prototypical RepRap successfully healed itself, printing a replacement for its own broken part.

By February 2008, the first fully operational RepRap, named Darwin, managed to print copies of over half of its own parts; later that year, a completed “child” machine, made largely of parent-printed parts, began building a grandchild. With a lot of help from human assemblers, extra parts, and raw plastic, the machine had managed a sort of preliminary lineage.

A pair of children’s shoes Bowyer printed with RepRap. When the kid outgrows the shoes, Bowyer says, “you could chuck the shoes back into the reprocessor, throw in an extra milk bottle, and print out a bigger pair.” (Photo: Adrian Bowyer/RepRap Wiki GNU 1.2)

Tech pundits greeted this news with great fervor. Many already saw 3D printing as the ultimate disruptor, a way to decentralize manufacturing in the same way the internet has decentralized information. A totally self-replicating printer would make readily available not only the means of production for a variety of objects, but the means of production of the means of production. “The future has already arrived,” announced BBC News. “Some claim RepRap could end poverty and halt global warming,” Seed Magazine added. The Guardian even predicted it would “revolutionize Christmas,” printing out toys left and right like an in-house elf.

Such things have not yet come to pass. For the moment, Bowyer treats his RepRap less like a revolutionary weapon and more like a useful pet. He prints coat hooks and labels for his garden, and makes small repairs on the family car. Thus far, his favorite RepRap story involves a scuba diver who printed multicolored plastic shells for a nearby population of hermit crabs. “I didn’t know that when I started [RepRap] I was going to solve the housing shortage,” he says, ”Unfortunately, not for our own species.”

Still, he is on board with this potential utopian vision. RepRap’s tagline is “Wealth without money,” and his introductory one-sheet speaks of “Darwinian Marxism… without all that messy and dangerous revolution stuff.” He gets excited about add-on recyclers that could use RepRap to transform plastic bottles into everything from shoes to cell phones. He and others are working to enable RepRap to work with many more materials, particularly metals, which would greatly expand its creative capacity.

An octopus born of a RepRap-printed mold. (Photo: Digital Nuisance/Flickr)

Plus, to some extent, he says, RepRap’s more potentially revolutionary features—its open-source plans and software, and its increasingly cheap asking price (depending on your preferred model, a complete kit currently goes for around $300)—were inevitable consequences of its original philosophical goal. “If you’ve got anything that copies itself, you’ve got to give it away” or spend your whole life in court, he points out.

Because Bowyer shares all of his designs and software publicly, RepRap’s initial following grew into an army of hundreds of volunteers, who built their own printers from his plans and then enhanced them with their own ideas. (“I used to boast that I had the largest research project staff of any university in the United Kingdom,” Bowyer says.) As the new RepRappers added and shared their tweaks, those that worked well caught on, and were incorporated into the mainstream design. Due to the nature of the beast, users can even level up their older RepRaps by using them to print improved parts. “It’s a bit like the way we made a labrador out of a wolf,” says Bowyer. “The fitness of the machine is decided by people.”

The RepRap army might have lost track of how many printers are out in the world, but they do know which RepRap is the closest to its ultimate target. RepRap Snappy, which is 73 percent self-replicable, was designed by RepRap community member Revar Desmera, and unveiled last September. Snappy, which looks like a colorful, inscrutable Lego building, snaps together, eliminating the need for screws or other metal attachments, and Desmera has designed plastic equivalents to replace certain metal parts. Though there are some vital parts, like motors and electronics, that can’t yet be 3-D printed, Desmera is confident that “100 percent replication will eventually happen” sometime in the next couple of decades, he writes in an email. (Bowyer is less certain, saying that while he thinks great improvements will be made, going from 98 percent to 100 percent “is going to be virtually impossible.”)

“I admit that I end up spending more time designing and printing upgrades to my 3D printers than I actually do printing non-printer parts,” writes Desmera. “It’s inspiring in its own right.” And so the dream of the self-printing printer inches closer to its goal, one layer of plastic at a time.

Naturecultures is a weekly column that explores the changing relationships between humanity and wilder things. Have something you want covered (or uncovered)? Send tips to cara@atlasobscura.com.

Follow us on Twitter to get the latest on the world's hidden wonders.

Like us on Facebook to get the latest on the world's hidden wonders.

Follow us on Twitter Like us on Facebook